Material properties of filaments to consider when 3D printing a functional product.

Source: ChatGPT 40

Comparison of 3D Printing Filaments with PEX

PEX (Cross-Linked HDPE)

Tensile Modulus (Young's Modulus): Approx. 1.0-1.5 GPa

Flexural Modulus: Approx. 0.8-1.0 GPa

Elongation at Break: Approx. 100-300%

Flexural Strength: Approx. 20-30 MPa

Impact Resistance: Good

Shore Rating: Typically around 60D (Shore D hardness)

Temperature Tolerance: Hot: Up to 95°C (203°F); Cold: Down to -40°C (-40°F)

UV Resistance: Moderate; can degrade with prolonged exposure

Pros:

- Good impact resistance and flexibility

- High chemical resistance

- Low thermal conductivity

Cons:

- Not suitable for very high temperatures

- UV resistance is limited for outdoor applications

3D Printing Filaments

1. ABS (Acrylonitrile Butadiene Styrene)

Tensile Modulus (Young's Modulus): Approx. 2.1-2.5 GPa

Flexural Modulus: Approx. 2.1-2.5 GPa

Elongation at Break: Approx. 2-5%

Flexural Strength: Approx. 70-90 MPa

Impact Resistance: Moderate

Shore Rating: Typically around 80D (Shore D hardness)

Temperature Tolerance: Hot: Up to 100°C (212°F); Cold: Down to -20°C (-4°F)

UV Resistance: Poor; may degrade with prolonged UV exposure

Pros:

- Good strength and durability

- High impact resistance

- Relatively easy to post-process

Cons:

- Requires a heated bed and enclosed printer to avoid warping

- Emits fumes during printing, requiring ventilation

2. PETG (Polyethylene Terephthalate Glycol)

Tensile Modulus (Young's Modulus): Approx. 1.5-2.0 GPa

Flexural Modulus: Approx. 1.6-2.0 GPa

Elongation at Break: Approx. 10-15%

Flexural Strength: Approx. 50-70 MPa

Impact Resistance: High

Shore Rating: Typically around 70D (Shore D hardness)

Temperature Tolerance: Hot: Up to 80°C (176°F); Cold: Down to -20°C (-4°F)

UV Resistance: Moderate; can degrade with prolonged exposure

Pros:

- Good flexibility and impact resistance

- Low warping and easy to print

- Less odorous compared to ABS

Cons:

- Can be more difficult to bond with adhesives

- May be less rigid compared to ABS and PEX

3. Nylon

Tensile Modulus (Young's Modulus): Approx. 1.5-2.0 GPa

Flexural Modulus: Approx. 1.5-2.0 GPa

Elongation at Break: Approx. 30-50%

Flexural Strength: Approx. 60-90 MPa

Impact Resistance: Excellent

Shore Rating: Typically around 60D to 75D (Shore D hardness)

Temperature Tolerance: Hot: Up to 120°C (248°F); Cold: Down to -40°C (-40°F)

UV Resistance: Poor; may degrade with prolonged UV exposure

Pros:

- High flexibility and impact resistance

- Good abrasion resistance

Cons:

- Challenging to print due to warping

- Requires high printing temperatures

4. TPU (Thermoplastic Polyurethane)

Tensile Modulus (Young's Modulus): Approx. 0.5-1.5 GPa

Flexural Modulus: Approx. 0.5-1.5 GPa

Elongation at Break: Approx. 300-600%

Flexural Strength: Approx. 30-50 MPa

Impact Resistance: Very high

Shore Rating: Typically around 85A to 95A (Shore A hardness)

Temperature Tolerance: Hot: Up to 80°C (176°F); Cold: Down to -30°C (-22°F)

UV Resistance: Moderate; can degrade with prolonged exposure

Pros:

- Highly flexible and durable

- Excellent impact and abrasion resistance

Cons:

- Can be challenging to print due to its flexibility

- May require special printer settings

5. PLA (Polylactic Acid)

- Tensile Modulus (Young's Modulus): Approx. 2.1-2.5 GPa

- Flexural Modulus: Approx. 2.1-2.5 GPa

- Elongation at Break: Approx. 2-5%

- Flexural Strength: Approx. 70-90 MPa

- Impact Resistance: Moderate

- Shore Rating: Typically around 80D (Shore D hardness)

- Hot: Up to 100°C (212°F)

- Cold: Down to -20°C (-4°F)

UV Resistance Poor: degrades with prolonged UV exposure

Pros- Good strength and durability

- High impact resistance

- Relatively easy to post-process

- Requires a heated bed and enclosed printer to avoid warping

- Emits fumes during printing, requiring ventilation

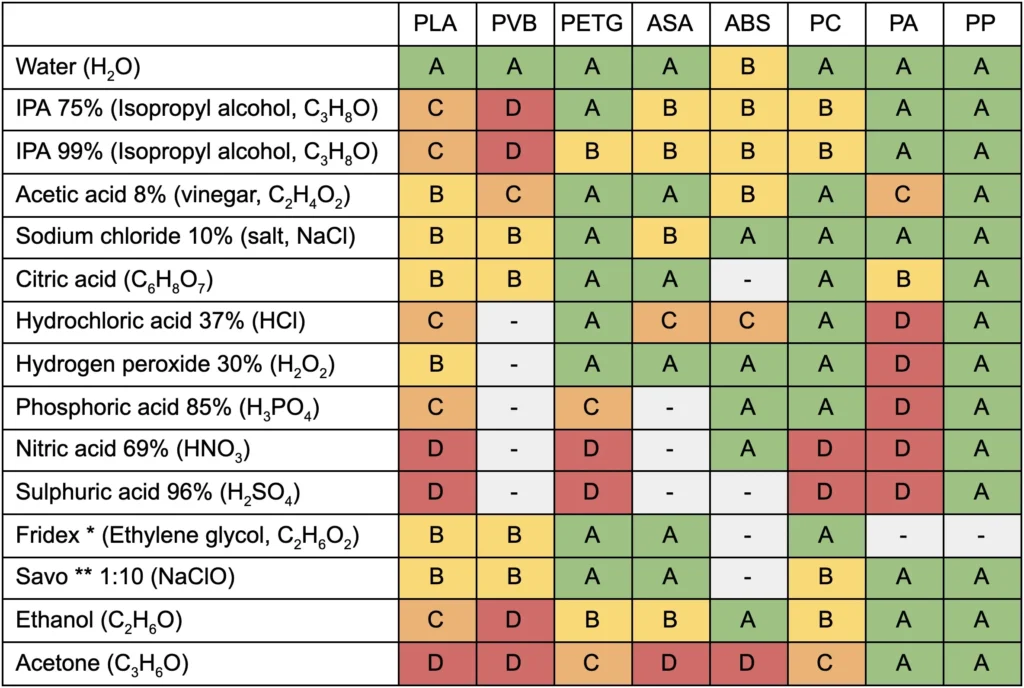

Chemical Properties

Chemical properties of filaments to consider when 3D printing a functional product.

Source: Chemical Properties of Common 3D Printing Filaments

Chemical Resistance Rating:

A – Resists very well. Polymer does not melt, absorb substance, or swell during a week’s immersion (less than 1% change in weight and dimensions).

B – Resists moderately to well. Slight swelling or change in weight (2 – 3% change in weight or dimensions).

C – Resists poorly. Significant swelling and change in weight of the test sample (4-5% change in weight or dimensions) occurs with prolonged exposure of the polymer.

D – Does not resist. A red colour indicates a significant change in weight, severe swelling (change in weight or dimensions over 5%) or complete destruction of the fibre (2).

Data for the evaluation of polymers were obtained from our measurements under laboratory conditions and from a scientific publication not named by Prusa

Summary

When selecting a filament for 3D printing, consider the specific requirements such as flexibility, strength, chemical resistance and environmental tolerance. ABS and PETG offer a balance between flexibility and rigidity, with PETG providing better impact resistance. Nylon provides high flexibility and impact resistance but can be difficult to print. TPU offers excellent flexibility and durability but requires careful handling during printing. Each material has its own advantages and disadvantages based on the application's needs.